HIGH MAST LIGHT POLES

DESCRIPTION

The high mast with raising and

lowering gear system is a safe system due to reliable service hoist which

raises and lowers the fixtures ring for maintenance purposes.

Raising & lowering

gear system consists of the following major parts as shown in our catalogue:

1- Head Frame.

2- Luminaries Ring.

3- Single or Double Drum Winch.

4- Portable power tool with

Portable Electrical Motor.

The raising & lowering

system is a special electromechanical arrangement which is procured by us .

High Mast Shape:

The high masts (15-40m) are usually made out of

continuously tapered steel shafts with polygonal shape of sixteen sides, with

dimensions and thicknesses complying to the structural design analysis and

suitable to suit the raising & lowering mechanism.

Shafts are made from steel

sheets folded to required shape and welded longitudinally by automatic arc

welding machine

Shafts are made out of multiple

segments depending on the height of the mast, each segment will have length of

not more than 12m, with minimum overlap of 1.5

times of the female segment across flat.

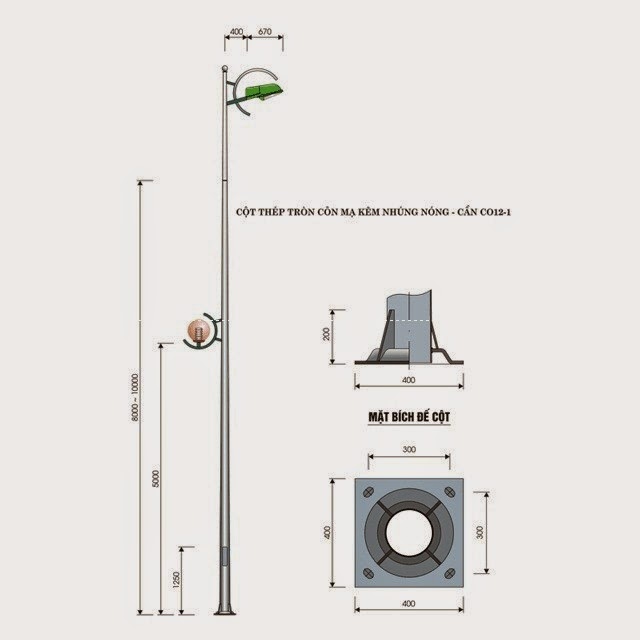

Circular or Square base plate

with holes suitable for the anchor bolts is welded to the bottom of the shaft

by double fillet weld according to international standard, base plate will be

open in the centre to allow cables in.

Base plate dimensions given in

our drawings are complying with structural design analysis and the foundation

requirements.

Anchor bolts to fix the base

plate to the concrete foundation are supplied with the required nuts and

washers and having the size and dimensions as per the structural analysis.

Shaft is provided with a door

opening at a convenient height with dimensions and size complying with the

requirements of the raising & lowering mechanism. Door opening is

reinforced to maintain shaft strength; In addition, a rubber gasket is fixed

around the door frame for weatherproofing.

Door cover is fixed to the

shaft by using steel Hinges.

An Earthing lug is welded

inside the shaft at the door opening level and equipped with the required

bolts, nuts and washers for earthing.

Straightness, tolerances and

plumbness of the pole are maintained within permissible limits according to

international standards.

DESIGN

Design wind speed is 160 Km/hr

or as per the customer request multiplied by gust factor of 1.3 (Gust speed is

208 Km/ hr or as specified in the project specifications)

Design of high masts is

performed utilizing Computer software to analyse the high mast shaft, base

plate and anchor bolts.

MATERIAL

Material used to fabricate the

high mast components will be in accordance of international standards and as

per the project specifications.

FINISHING

No welding, cutting or drilling

is done after galvanising.

The anchor bolts including nuts

and washers are hot dip galvanised according to ASTM A 153.